Type B (EN 1337 – 3)

ELASTOMERISCHE STÜTZEN

Type C (EN 1337 – 3)

Increased water slides supports

Type B/C (EN 1337-3)

Type C-PSP (EN 1337-3)

Steel-elastomeric supports provide safe, reliable and maintenance-free bridges and comparable constructions for more than 30 years. They transmit large vertical loads and compensate tangential deviations as well as translating displacements with small limitations in the support area.

Operating mode

The special assembly of the Leuschplast GLT reinforced elastomeric support provides secure, reliable and maintenance-free transmission of heavy vertical loads due to its own weight and work load. At the same time, tangential deviations, e.g. caused by deflection, and translational movements, e.g. due to thermal changes will be compensated by deformation of the low-quality high quality elastomer.

High quality steel plates are used as intermediate reinforcement layers together with the elastomer, which is very resistant to aging and to the conditions

meteorological data to vulcanize elastomeric rubber-coated Leschuplast GLT steel at its own production site. The results of assembly in layers, the reinforced plates are protected against corrosion and support the endurance of our wearers. The use of different types of chloroprene and high quality natural rubber allows the application of supports at temperatures ranging from – 40 0C to + 50 0C (temporarily up to + 70 0C) and protection against environmental and weather influences, especially against ozone and ultraviolet rays.

In order to be certified with the production of elastomeric supports according to DIN EN 1337-3, a series of tests have been successfully carried out. These tests were, for example:

compression-resistance

-the elastic modulus (even at low and very low temperatures and aging)

-Shearing resistance (even after aging)

-Resistance to repeated compression tasks

– Ozone resistance

At our place of production we produce Leschuplast GLT elastomeric elastomeric supports according to DIN ENE N 1337-3. This standard is built by construction authorities and is applied across the EU. According to the regulations in force, our supporters are subject to continuous external quality control. Internal quality control takes place through our quality assurance department. After successful CE certification, we have the right to affix the CE mark to our holders according to the compliance certificate EG 0432-CPD-223286. in addition to the corresponding documents, conformity of production according to DIN EN 1337-3 is demonstrated by this.

Paragraph 4, DIN EN 1337-1: 2000 states: “Supports shall be designed to allow the intended movements with as low a response as possible.”

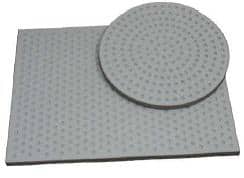

This demand is met by our flexible production. Our high quality Leschuplast GLT elastomeric reinforced elastomeric supports according to DIN EN 1337-3 can now be manufactured at any length and width between 100 and 1000 mm with a total height of 400 mm. Round shapes up to 1000 mm are also possible. The Leschuplast GLT offer exceeds the standard installation and allows a low-response support design according to DIN EN 1337-1: 2000, using these special production facilities.

Our flexible production also offers additional benefits:

-Many design opportunities by flexibly adapting the size of the supports;

– standard elastomer for supports with 0.9MPa modulus of elasticity at CR and NR;

-Specific natural LPGLT 115N with 1.15 MPa elasticity module for better flexural adaptation;

– All thicknesses of the elastomeric layer allowed according to DIN EN 1337-3 (5-25 mm) are possible;

– Larger elongated reinforced steel for reducing the size of the support are possible;

-Profile steel sheets, drill holes, threaded holes, dowels, and plate grooves are possible.

F type unreinforced supports: Normally we also produce Leschuplast GLT type F non-reinforced bearings in accordance with DIN EN 1337-3 with the same care and the same high quality materials.

For more than 30 years, elastomeric supports have reliable, reliable and maintenance-free support for comparable bridges and structures. This superior quality is made by our experienced, experienced specialists who produce Leschuplast GLT elastomeric supports according to DIN EN 1337-3 with modern manufacturing facilities. The internal quality control constantly performed by our quality assurance department together with the external quality control performed by an independent testing institute ensures superior manufacturing quality that we can “build”.

|

|

Leschuplast GLT Type A armed elastomeric elastomeric brackets are fully elastomer-coated and single-plate steel. These supports are designed to transmit tangential deviations and low translational loads to high, reliable, reliable and maintenance-free vertical loads. All the response forces will be transmitted to the foundation surfaces by the elastomer. |

|

|

Leschuplast GLT B-type elastomeric elastomeric bearings are completely elastomer-coated and armored with at least two steel plates. These supports are chosen when tangential deviations are displacement displacements too large for Type A. All response forces will be transmitted to the foundation surfaces the elastomer. |

The foundation surfaces must be smooth, horizontal, level and cleaned by grease and oil. Level differences should be compensated with a mortar if necessary. Mortar tested in accordance with DIN 1045.

The lateral surfaces of the foundation must be free and unformed in deformation.

The Type B support is usually installed on a smooth, firm mortar. In the upper part, the shuttering must be mounted close to the side surfaces of the support to prevent the concrete from penetrating between the support and the formwork. The open spaces between the foundation screed and the formwork can be filled with polystyrene or similar material. The surface of the support and the supported component must be in direct contact. There must be no sheets between them.

Installing two or more consecutive strings is not allowed. Installing the supports side by side is only allowed if the stiffness is equal or the supports are almost equal. The use of other types of supports is only possible if the same type of foundation supports are used for individual foundation screeds.

Type C with dowels

For installation of anchored elastomeric supports, base holes, double holes and grooves for their components should be provided.

After the shuttering has been removed, the surface of the molded foundation has to be smooth. After reinforcement, the supports are installed and the components are filled.

At the top of the rack, the same method is used as the uncoated supports.

C-PSP tip with profiled steel plates

The Type C-PSP Holder should be installed with a profiled steel plate in the mortar mortar. The set height level will be provided using the feathers. After hardening, the feathers are removed.

Structural design

BSL reinforced steel brackets are manufactured at a standard thickness of 13, 18 and 25 mm. Other thicknesses are possible. They are composed of special gray high-grade elastomer layers and steel reinforcement as well as a PTFE layer with embossed grooves to improve long-term friction. The gray elastomer is more advantageous than the black elastomer regarding the bleaching of the concrete.

Application

The increased slip method replaces the traditional production of bridges across valleys and scaffolding or beams. The advantage of the concrete casting method on the site and the prefabricated construction is thus successfully combined. The name of the WATER SPEAKING METHOD indicates a mechanized method of building large bridges. In a stationary formwork behind the counter, the superstructure is produced in individual work cycles. Individual pieces are immediately concreted in succession and connected together with bending resistance by pretensioning. The central pre-stressed superstructure is moved by hydraulic presses intermittently in the longitudinal direction. Underneath the superstructure, Leschuplast GLT supports are created specifically for increased BSL water sliding, which move on sliding plates with friction. It must be lubricated with Leschuplast GLT type BSL-SF silicone grease. the edges of the stainless steel plate must be rounded. The bridge feed must be parallel to the support.