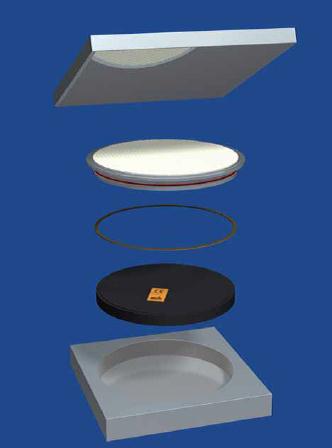

Container bearings have been used for many years and are a type of support with proven capabilities. By combining an unstained elastomeric support (natural rubber) into a steel casing that is enclosed on all sides (the container), it is possible to transmit large vertical loads on a relatively small surface. The dimensions of the container bearings depend on the admissible elastomer pressure and the admissible concrete pressure.

Bearing bearings are designed and manufactured in accordance with 1337-5 and are labeled with a relevant CE marking.

reazem tip oala” width=”484″ height=”91″

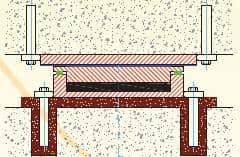

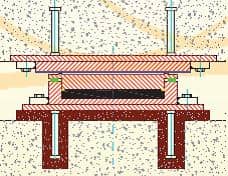

Action mode

The elastomer cushion located in the container is non-compressible and behaves like a liquid at high pressures. Deformability allows tilting of the piston on all axes.

The three-seal sealing system prevents dust and moisture penetration as well as leakage of elastomeric pressure.

- a brass seal prevents leakage of the elastomer between the container and the piston under high pressure.

- A special synthetic secondary seal above the brass prevents the moisture from entering the container.

- An additional external seal prevents the penetration of dust and water (spraying / splashing)

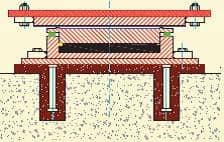

The difference between the types of reciprocating bearings (fixed, unidirectionally fixed, sliding in all directions) is the design of the piston.

The sliding elements are a recessed PTFE recessed disk in the piston and 1.4404 grade austenitic steel plate.

The sliding surface (PTFE disc) is designed and dimensioned to EN 1337-2.

Bearing bearings are generally uncoated to the structure (minimum load sufficiently large).

If additional anchorage is required due to real load combinations, this can be done by anchor plates and additional dowels.

The standard bearing does not require anchor plates for the simultaneous effects of vertical and horizontal loads.

pot type ” width=”496″ height=”227″

Translation Movement:

The technical sheets show the main dimensions of the bearing according to its type in correspondence with the minimum displacement (± 50 mm) and the horizontal loads listed.

Higher displacements as well as vertical and horizontal deviation loads are possible on request.

Concrete pressure:

The concrete pressure is analyzed according to DIN 1045-1. Design requirements are generally met with a minimum grade of C30 / 37 concrete when the Ac1 load spreading area is approx. 1.8 times the container surface (a x b).

Anchor methods:

Supports can support the designated horizontal loads without additional anchorages in the structure if the minimum vertical load is at least 50% of the maximum vertical load and more, the horizontal load does not exceed 10% of the maximum vertical load (with TGe and TF). The need for anchoring must be checked if this combination of load is not given. The following example shows some anchoring methods. These methods can also be applied to spherical bearings.