The expandable cord is a very flexible seal made of thermoplastic elastomer (TPE) and has the ability to expand. It is used to stop infiltrations through the joints and spaces that are created by casting a new concrete over the old one, having the advantage of applying directly to the old concrete by gluing or mechanical fastening. The expandable cord ensures controlled sealing of construction joints in concrete structures.

1. Types / Sizes

| Types / Sizes (mm) |

5 x 20 |

10 x 20 |

15 x 20 |

20 x 20 |

20 x 25 |

| Delivery length (ml) |

25,00 |

10,00 |

10,00 |

10,00 |

5,00 |

| Packaging mode |

Roll |

Roll |

Roll |

Roll |

Roll |

Expandable cord types

2. Material

The expandable cord is made of thermoplastic elastomer (TPE). Thanks to the highly elastic material, welding up to 300% is possible. This allows sealing of joints without cracks.

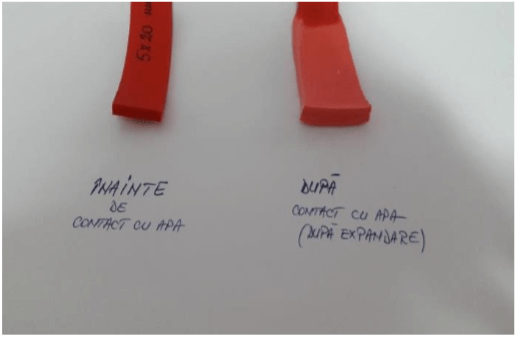

The TPE dilation rubber is made of ductile flexible acrylic polymers that can store water inside its molecular structure by increasing the volume. In contact with water it increases its three-dimensional volume without changing its homogeneous structure of the matrix of polymers. By expansion, the TPE expansion profiles will be pressed to the surrounding surfaces and thus seal the construction joints against penetration of the water. Evacuation of the dilatation material from the change of water levels and partially dry areas is impossible.

Material properties:

- Presentation: red, rubber-elastic, homogeneous

- Density: 1.26 g/ cm3

- Weight loss: 77. 6 greut. %

- Dilatability after (weight increase)

– stored under alkaline conditions: 18 d=282 greut. %

– stored under acidic conditions (pH 4.5): 14 d=178 wt%

– stored in distilled water: 14 d=472 wt%

- Expansion pressure: 0.72 N/ mm2

- Flammability: building material class B2 according to DIN 4102-1

3. Installation recommendations

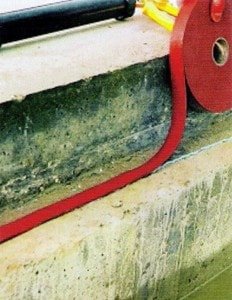

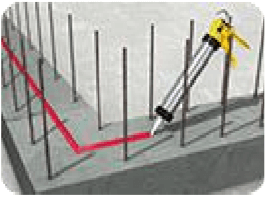

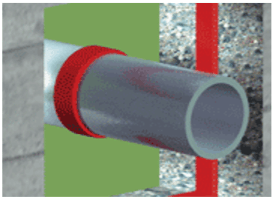

The substrate must be degreased, cleaned of dust, cement, dirt and other particles. Before applying the TPE expansion profiles, the surface water must be dried. Application should take place in a very short time before concreting (to avoid premature dilation due to rain). The TPE expansion rubber profiles must be perfectly symmetrical on the substrate prepared with a silicone fastener. To prevent leakage of water and to ensure pressure on all sides, the TPE expansion profiles should be placed perfectly symmetrically along the substrate.

Installation variant no. 1: Silicone fixing

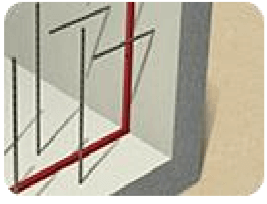

Installation variant no. 2: Point-to-point fixation

Installation variant no. 3: Mounting with mounting net

The depth of concrete coverings should be at least 8 cm. For thicknesses of concrete structures up to approx. 30 cm the installation must be centered, for thicknesses greater than 30 cm, the installation must be eccentric on the water side, taking into account the depth of the coating. The grooves of the TPE expansion profiles must be connected to the head. During concrete casting special care must be taken to ensure that the TPE expansion profile is completely covered with concrete.

4. Advantages of TPE expansion profiles:

- Reliable expansion capacity

- Reversible dilation behavior

- Higher compatibility against chemicals

5. Application examples:

- Sealing of horizontal and vertical work joints between old and new concrete

- On flat or irregular surfaces (being flexible, it can be molded on any irregularity of the surface)

- For the sealing of the joints and the spaces created by the casting of the concrete, especially at the connection between the horizontal and the vertical elements: the connection between the vertical walls and the basements of the basements, basins, swimming pools, decanting / treatment stations

- For sealing joints between plates For sealing the spaces that occur when the pipes and pipes pass through the concrete (it is mounted around the pipe / pipe